Transformers and Switchgear

Advanced engineering, world-class quality control standards, and competitive rates – with the advantage of shorter time lines

-

Global standards for safety, quality, delivery, and cost

-

Shorter timelines (often MUCH shorter)

-

In-house expertise (software and control engineering)

-

Decades of continual, failure-free operation

-

Next generation switching and cyber security

-

Best-in-Class Engineering

-

Procurement / Manufacturing

-

World Class Quality Standards

-

APQP Standards

-

Modern Testing / Certification

-

Deployment Services

-

Technical Transparency

-

Global Reach

Navigating a Distressed Market

Blueflux Delivers Value & Reliability To Your Supply Chain

A Market in Distress

THE ELECTRIC GRID FACES CONSIDERABLE CHALLENGES

Lead times for transformers have skyrocketed by 443% since 2020 due to:

Demand Outpacing Supply:

Infrastructure upgrades, growth in renewable energy, and the transition to electric vehicles.

Supply Chain Disruptions:

Cybersecurity concerns and a shift from traditional suppliers.

Critical Component Shortages:

Raw material scarcity and a lack of skilled labor.

Grid Reliability Concerns:

The rise of intermittent renewable energy sources like solar and wind causes grid frequency and voltage fluctuations, leading to potential blackouts and brownouts.

Cybersecurity Threats:

The electrical grid is a prime target for cyberattacks, with traditional transformers being vulnerable to exploitation.

Blueflux is committed to providing reliable, high-quality grid infrastructure equipment with shorter lead times, ensuring a stable and secure electrical grid for the future.

Who We Are

WE ARE SENIOR ENGINEERS, PROCUREMENT AND MANUFACTURING EXPERTS.

OWNERSHIP & CAPABILITIES:

A US-based, female/minority-owned company with advanced engineering expertise and decades of practical experience.

GLOBAL REACH:

Access to global markets and talent for competitive costs and timing.

STRATEGIC FOCUS ON MANUFACTURING:

Combining access to critical materials and a highly educated, skilled workforce in India, with proven world-class quality control methods managed from the US.

ROBUST SUPPLY CHAIN:

Experienced team with stringent quality control to ensure performance to western standards.

ACCESS TO TALENT:

A world-class team of skilled professionals ensuring product effectiveness, safety, quality, and timely delivery.

INTEGRATED APPROACH:

A centralized framework that shortens timelines, reduces errors, and maintains superior control of standards.

The Value We Deliver

HIGH-QUALITY EQUIPMENT • COMPETITIVE PRICING • ADVANTAGED TIMELINES

Engineering Expertise:

- Engineering expertise and shorter lead times through prequalified, highly trained global partnerships.

- End-to-end capabilities from complex engineering and testing to commissioning support.

Proven Quality:

- Rigorous quality controls to meet the highest western standards. Blueflux engineers write IEEE standards.

- World-class APQP (Advanced Product Quality Planning) includes testing and validation at the material, component, and assembled unit phases, ensuring the highest quality and reliability.

Competitive Pricing:

- Efficient global partnerships and in-house expertise to deliver cost-effective solutions.

- Diverse selection of transformers to meet various needs, including power, current, voltage, isolation, grounding, distribution, and dynamic reactive power compensation transformers.

Shorter Timelines:

- One team, one goal: US-based sales and management team works closely with our engineering and manufacturing teams to ensure timely communications and delivery.

- Focus on visibility and clarity at every project stage, ensuring faster turnaround times and efficient project completion.

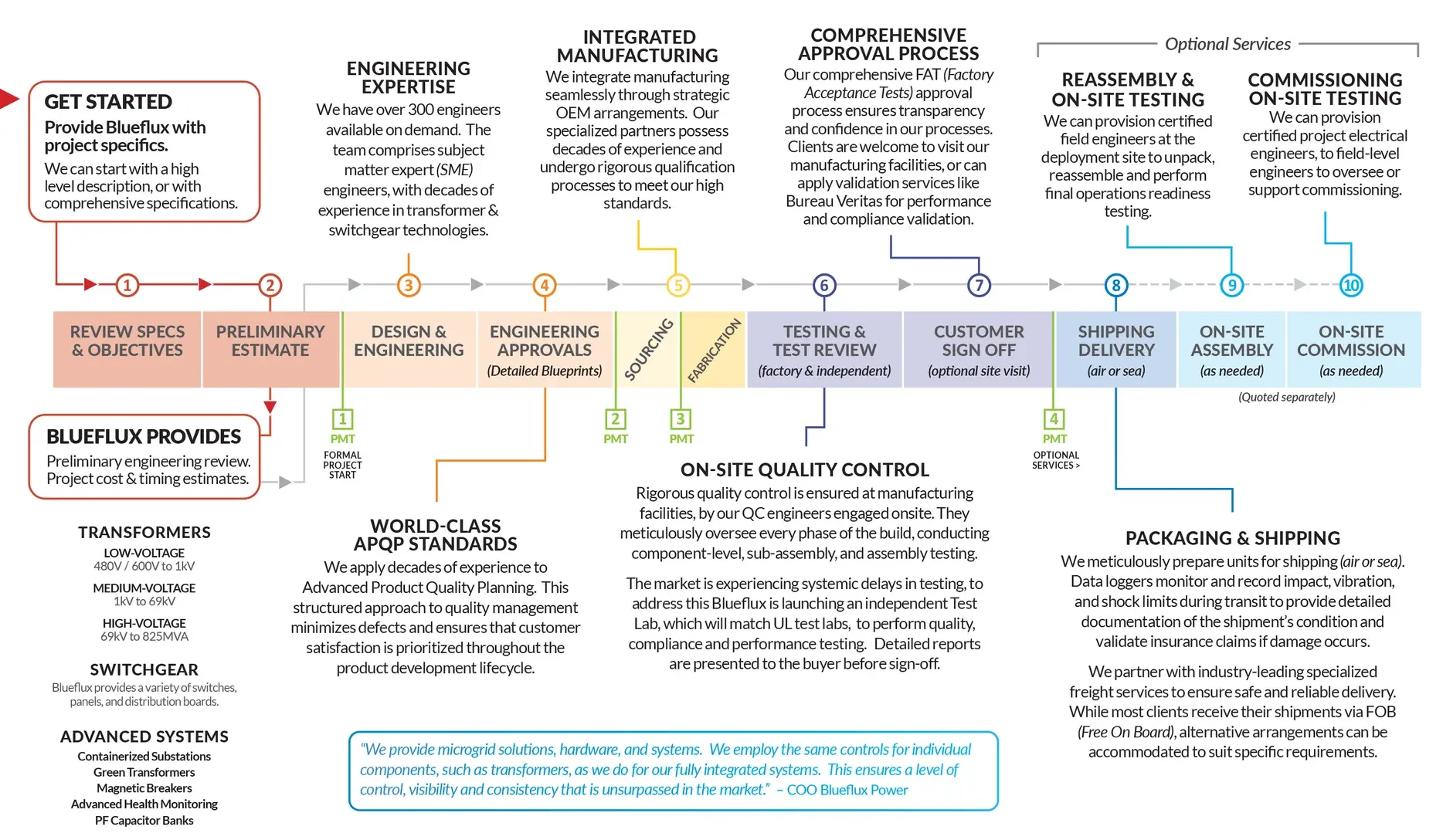

The Process We Apply

WORLD-CLASS QUALITY CONTROL METHODS, TESTING AND STANDARDS

Advanced Product Quality Planning (APQP):

We utilize a rigorous APQP process to identify and mitigate potential risks throughout the entire development cycle, minimizing defects and ensuring a smooth transition from design to production.

Design for Manufacturing and Assembly (DFMEA) & Product Failure Mode and Effects Analysis (PFMEA):

Our DFMEA and PFMEA processes involve proactively identifying potential failure modes during the design phase. This allows us to engineer solutions to prevent these issues before they occur, further enhancing transformer reliability.

Rigorous Testing:

Every Blueflux transformer undergoes a comprehensive battery of tests, including routine, type, special, and commissioning tests. This ensures that we meet strict performance and safety standards before your order leaves our facility.

Real-Time Video Documentation:

We maintain a transparent and accountable manufacturing process by recording all assembly stages with high-definition video. This creates a detailed audit trail for quality control purposes and provides valuable documentation for future reference.

Supply Chain Reliability

GAIN CONTROL OF YOUR CRITICAL EQUIPMENT SUPPLY CHAIN

Supply Availability:

Strategic relationships = leveraged buying, more predictable supply.

Enhancing Control Standards:

Advanced APQP standards = quality, consistency & compliance.

Embracing Innovation:

Next Generation technologies = faster migration to modern grid capabilities.

Improving Existing Assets:

Advanced software = more visibility & control to protect critical infrastructure.

Developing Partnerships:

Direct global access = to supply-strained hardware & talent.

Integrated Solutions:

Modularized systems reduce on-site build times and cost vs. stick builds.

“By 2026, 50% of G20 members will experience monthly electricity rationing, turning energy-aware operations into either a competitive advantage or a major failure risk.“

Source: Gartner Predictions for IT Organizations and Users in 2024 and Beyond.

“Transformer shortages are a critical bottleneck hindering the clean energy transition. We need innovative solutions to bridge the gap.”

KAVYA BALARAMAN | December 21, 2023

Source: _Latitude Media

“A recent study by the American Council for an Energy-Efficient Economy (ACEEE) found that transformer shortages cost US businesses an estimated $100 billion annually in lost productivity.”

Kevin Kuhlman, Senior Policy Analyst,

American Council for an Energy-Efficient Economy (ACEEE)

Source: US Struggles to Make Enough Transformers

Podcast November 15th, 2023

Tailored Manufacturing Solutions

Modern manufacturing expertise and robust quality controls ensure strict adherence to high standards, including certifications compliance reinforced by insurance & warranty coverages.

-

MADE-TO-STOCK (MTS)

Products produced in anticipation of demand, with inventory readily available for immediate purchase, allowing for quick fulfillment and reduced lead times.

-

MADE-TO-ORDER (MTO)

Goods manufactured based on specific customer orders, enabling customization and tailored production to meet individual customer requirements.

-

CONFIGURABLE-TO-ORDER (CTO)

Products with pre-defined configurations that can be customized within set parameters based on customer preferences, balancing flexibility & efficiency

-

ENGINEERED-TO-ORDER (ETO)

Highly customized products designed and produced based on unique customer specifications, often involving complex engineering with shorter lead times.

Next Generation Technologies

Voltage, Isolation & Grounding Transformers in a range of sizes and configurations

-

AI-Based Control Systems

-

Advanced Health Monitoring

-

Containerized Substations

-

Green Transformers

-

Magnetic Breakers

-

PF Capacitor Banks

Formats & Size Ranges

Low-Voltage - 480V / 600V to 1kV

Transformers:

Various formats, sizes and capacities.

Switchgear:

Circuit breakers, fuses, and switches, including Fuse Switches, Changeover Switches, Distribution Fuse Boards and industrial Switch Boards (SPN & TPM 2 to 16 way)

Service Entrance Equipment:

Such as meter sockets, main circuit breakers, and grounding equipment.

Voltage Regulators:

Used to regulate and stabilize low-voltage electrical signals in various electronic devices.

Protective Equipment:

Such as surge protectors, lightning arresters, and other devices that protect electrical systems from damage due to power surges, lightning strikes, or other transient events.

Medium-Voltage - 1kV to 69kV

Power Transformers:

Up to 20 MVA, 66 kV Class.

Distribution Transformers:

Up to and including 2500 kVA, 33 kV Class.

Corrugation Transformers:

Up to 1000 kVA, 22 kV Class.

Special Application Transformers:

EMU, LOCO Transformers for Railway applications.

Cast Resin Transformer (CRT):

Up to 1600 KVA.

Oil Cooled Transformer (OCT):

Up to 500 KVA.

Additional Capabilities:

In addition to Dynamic Reactive Power Compensation, and Furnace Transformers, Solar Transformers, and Amorphous Transformers, we also supply a variety of switches, including; Fuse Switches, Changeover Switches, Porcelain Fuse Units and Cutouts, Distribution fuse boards and industrial type switch boards, and Distribution Boards (SPN & TPN 2 to 16 ways).

High-Voltage - 69kV+

Power Transformers:

20MVA to 315 MVA (3-Phase) / 825 MVA (Single-Phase)

Current Transformers:

Up to 400 kV. (Hermetically sealed, oil impregnated, paper insulated, and oil filled outdoor type. Over 20,000 sold over 30 years with excellent service records)

Voltage Transformers:

Up to 245 kV. (Hermetically sealed, oil impregnated paper insulated, oil filled, porcelain type outdoor electromagnetic potential transformers)

Transformer Bushing:

52kV – 420 kV voltage class and rated current up to 3150A. (Hermetically sealed, oil impregnated paper condenser bushings)

Tap Change Gear:

Various types of On Load & Off Load Tap changers to suit the number of taps, current rating, step voltage, and number of poles.

Engineered Excellence from Start to Finish

Blueflux ensures top-tier electric equipment by overseeing the entire process, leveraging extensive engineering expertise from architecture to field deployment. With decades of procurement and manufacturing experience, we implement world-class quality control measures and rigorous testing protocols. Partnering with leading shippers, we facilitate seamless shipping and offer expert talent for on-site assembly and commissioning.

NORTH AMERICAN DRY-TYPE TRANSFORMER MARKET

10.3%

CAGR

(2020-2027)

$16.4B

N. American Market

(2023)

$1B

India Transformer

Exports By 2025

“The average lead times to procure a distribution transformer in the US have risen 443% since 2020”

– US ENERGY DEPT.